The hand wipe manufacturing industry occupies a critical space in the global hygiene market. Once a peripheral player, it has emerged as an indispensable component of health, sanitation, and convenience, especially in light of recent global health crises. The industry’s evolution is shaped not only by innovations in chemistry and packaging but also by a wide spectrum of economic factors. These elements range from raw material costs and labor rates to macroeconomic indicators like inflation and currency fluctuations. This article offers an in-depth exploration of the economic variables that influence hand wipe manufacturing, explaining how each factor impacts production, pricing, and global competitiveness.

Raw Material Costs and Availability

At the core of hand wipe production lies a reliance on specific raw materials such as nonwoven fabrics, alcohol, preservatives, and packaging components. Prices for these materials are often volatile, subject to market trends, geopolitical tensions, and supply chain disruptions. For instance, fluctuations in petroleum prices directly affect the cost of synthetic nonwovens. Additionally, natural fiber availability, such as cotton or cellulose, may be impacted by seasonal harvests or climate conditions. Manufacturers must engage in strategic sourcing and long-term supplier agreements to manage these risks. Furthermore, when raw materials become scarce or expensive, it places pressure on profit margins, compelling companies to adjust their formulations or seek alternative sources that meet regulatory and safety standards.

Labor and Workforce Considerations

Labor constitutes a significant portion of manufacturing expenses. The cost and availability of skilled and unskilled labor influence factory operations, particularly in regions where automation has not fully replaced manual labor. Rising wages, shifts in labor laws, and changing workforce demographics further complicate this landscape. For example, stringent labor regulations in developed economies often necessitate higher investment in employee welfare and safety programs. Meanwhile, labor shortages can lead to increased reliance on temporary staff, driving up operational costs and potentially affecting product quality. Balancing cost efficiency with ethical labor practices is not merely a corporate responsibility but a strategic necessity, especially for companies aiming to establish long-term credibility and consumer trust.

Energy and Utility Expenditures

The manufacturing process for hand wipes, especially in large-scale facilities, requires substantial energy inputs. These include electricity for machinery, heating for processing chemicals, and water for certain stages of production. As global energy prices fluctuate, driven by market speculation and geopolitical instability, so too do the operating costs for manufacturers. Companies located in regions with high energy tariffs may find themselves at a competitive disadvantage. Consequently, energy efficiency has become a priority. Modern facilities often invest in renewable energy solutions, such as solar panels or energy recovery systems, to mitigate long-term costs. These investments, while capital-intensive upfront, can yield significant savings and environmental benefits over time.

Transportation and Logistics Dynamics

The global nature of the hand wipe supply chain necessitates efficient transportation and logistics. Whether importing raw materials or exporting finished goods, manufacturers are heavily dependent on a functioning global trade system. Fuel prices, port congestion, and customs delays can significantly affect delivery schedules and costs. Additionally, the COVID-19 pandemic underscored the vulnerability of international supply chains, prompting a reevaluation of logistics strategies. Many companies are now exploring nearshoring and regional distribution centers to buffer against future disruptions. The ability to adapt to logistical challenges is crucial for maintaining a steady supply chain, meeting customer expectations, and minimizing financial losses from delayed shipments.

Inflation and Currency Exchange Rates

Inflation directly impacts production costs by increasing the price of raw materials, labor, and utilities. Simultaneously, fluctuating currency exchange rates can either benefit or burden international transactions. For manufacturers operating across borders, currency devaluation in supplier countries can reduce material costs, while appreciation in consumer markets may hurt export competitiveness. Strategic currency hedging and multi-currency pricing models are commonly employed to mitigate such risks. Moreover, understanding local inflationary trends enables companies to forecast budget adjustments and pricing strategies more accurately. These economic indicators are essential for both short-term planning and long-term investment decisions within the industry.

Government Policies and Trade Agreements

National policies, including tariffs, subsidies, and trade agreements, exert a profound influence on the hand wipe manufacturing sector. Tariffs on imported raw materials can raise production costs, while export incentives may bolster international sales. Additionally, environmental regulations often require companies to invest in sustainable practices, which may involve higher upfront costs. Government grants and tax breaks aimed at promoting green technologies can offset these expenses. Trade agreements like NAFTA or the EU Single Market also facilitate smoother transactions by standardizing tariffs and compliance requirements. Navigating these complex frameworks requires legal acumen and proactive engagement with policy developments to remain compliant and competitive.

Market Demand and Consumer Behavior

Economic conditions significantly shape consumer behavior, which in turn drives market demand. During periods of economic growth, consumers are more likely to spend on premium or specialized hygiene products. Conversely, in downturns, purchasing patterns shift toward cost-effective options. The hand wipe industry must remain agile, capable of adjusting product lines and marketing strategies in response to these trends. The rise of e-commerce and direct-to-consumer models also introduces new economic considerations, such as digital marketing expenses and distribution logistics. Understanding the elasticity of demand helps manufacturers optimize their offerings and ensure financial resilience amid shifting economic climates.

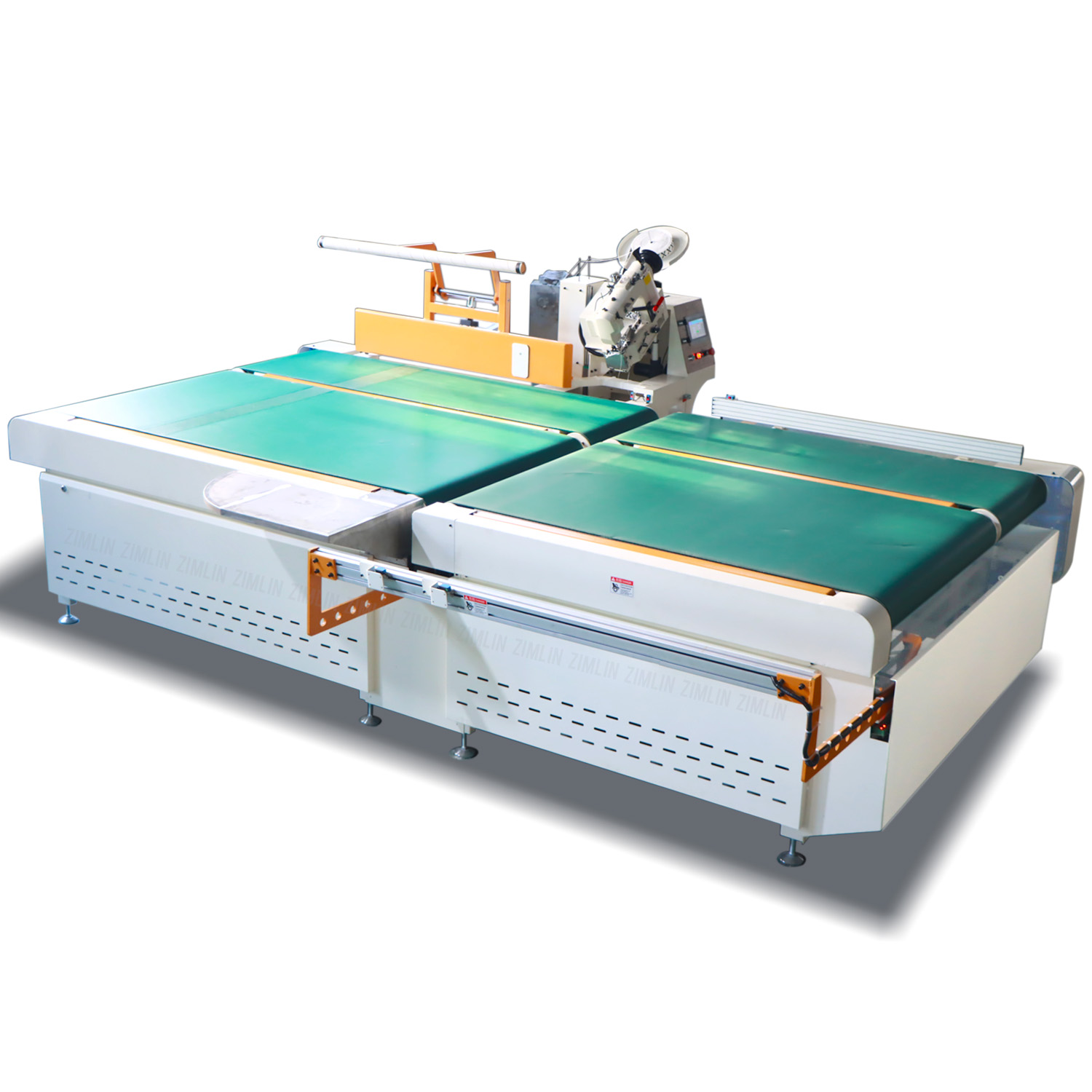

Technological Investment and Capital Expenditure

Advancements in automation, material science, and quality control technologies offer competitive advantages but require substantial capital investment. Economic conditions influence the availability and cost of financing for such projects. In low-interest environments, manufacturers may be more inclined to upgrade equipment or expand capacity. However, during periods of economic uncertainty, capital expenditure often slows down. Evaluating the return on investment for technological upgrades is essential, especially when balancing the immediate cost against long-term productivity gains. Companies that strategically invest in innovation during favorable economic cycles often emerge stronger and more agile in the face of future challenges.

Global Competition and Pricing Pressures

As more players enter the market, competition intensifies, driving down prices and compressing margins. This dynamic is particularly pronounced in commoditized product categories where brand differentiation is minimal. Manufacturers must navigate the delicate balance between cost control and product quality. Competitive pricing strategies, such as value bundling or tiered offerings, can help attract a broader consumer base. Moreover, maintaining high production standards is essential for brand reputation, especially in health-sensitive markets. Understanding the global competitive landscape enables companies to identify gaps, innovate within their niches, and allocate resources more effectively.

Supply Chain Resilience and Risk Management

Economic instability often exposes vulnerabilities in supply chains. Events such as political upheaval, pandemics, or natural disasters can disrupt the flow of goods and inflate costs. As a result, many hand wipe manufacturers are investing in supply chain resilience strategies. These include diversifying supplier bases, increasing inventory buffers, and employing advanced forecasting tools. Resilience is no longer a supplementary objective but a core component of economic strategy. The ability to absorb shocks and maintain continuity is a key differentiator in an increasingly volatile global marketplace.

The Role of Branding and Product Differentiation

In a crowded market, branding and product differentiation play a critical role in economic viability. Companies that successfully position their hand wipes as superior in quality, efficacy, or environmental impact can command premium prices. This differentiation often requires investment in research and development, consumer education, and targeted marketing. Economic conditions influence the resources available for these initiatives. However, well-executed branding can create loyal customer bases and stable revenue streams, insulating companies from price wars and economic downturns. It is within this framework that the strategic use of private label wipes has gained traction, allowing retailers to align product offerings closely with their brand ethos and consumer expectations.

Shifts in Hygiene Standards and Regulations

Health crises and evolving consumer awareness have led to stricter hygiene standards globally. Regulatory changes can necessitate alterations in formulation, labeling, and testing procedures, all of which carry economic implications. Compliance costs can be significant, especially for companies operating in multiple jurisdictions with differing requirements. However, proactive compliance can serve as a market advantage, demonstrating commitment to quality and safety. The ability to anticipate and adapt to regulatory shifts is a hallmark of resilient hand wipe manufacturers, particularly those aiming to serve international markets with diverse legal landscapes.

The Influence of Sustainability and ESG Metrics

Environmental, social, and governance (ESG) criteria are increasingly influencing investor and consumer choices. Manufacturers are under pressure to adopt sustainable practices, from biodegradable materials to low-emission manufacturing processes. While these changes often involve higher costs, they also open doors to new market segments and investment opportunities. Companies that align with ESG values are more likely to attract environmentally conscious consumers and secure long-term capital from sustainability-focused funds. For hand wipe manufacturers, integrating ESG principles into core business strategies is not only an ethical imperative but also a sound economic decision.

Conclusion

The hand wipe manufacturing industry operates at the intersection of health, convenience, and global economics. Understanding the multifaceted economic factors that shape this sector is essential for stakeholders ranging from investors and executives to policy makers and consumers. From raw material costs and labor dynamics to regulatory compliance and sustainability, each variable plays a critical role in determining operational success and market relevance. By adopting a strategic, informed approach to these economic influences, hand wipe manufacturers can not only navigate present challenges but also position themselves for sustainable growth in an ever-evolving global marketplace.