The aerospace industry is one of the most innovative and high-precision sectors globally, where cutting-edge technology plays a crucial role in ensuring the safety, reliability, and performance of aircraft and spacecraft. In recent years, CNC machining has emerged as a game-changer in aerospace manufacturing. With its precision, efficiency, and versatility, CNC machining is revolutionizing the way parts and components are produced, significantly influencing the industry’s growth. This article will explore the ways in which CNC machining is contributing to aerospace manufacturing, the benefits it offers, and its future potential in the industry.

The Evolution of CNC Machining in Aerospace

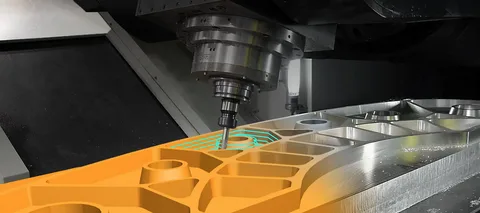

CNC (Computer Numerical Control) machining has evolved significantly since its inception, becoming a crucial technology for aerospace manufacturing. Early aerospace manufacturing processes relied heavily on manual labor and traditional machining techniques. However, as the demand for more complex and precise components grew, especially for jet engines, airframes, and spacecraft, CNC machining emerged as a necessary solution to meet the industry’s high standards. The ability of CNC machines to create highly detailed parts with extreme precision has made them indispensable in the aerospace sector.

The rise of CNC machining growth in aerospace has also been facilitated by advances in automation and computer programming. Machines can now operate autonomously, reducing human error and increasing production speeds. These advancements have enabled manufacturers to produce more intricate components that were previously too difficult or costly to make using traditional methods. Today, CNC machining is a cornerstone of aerospace manufacturing, allowing companies to meet the strict tolerances and quality requirements of the industry.

CNC Machining’s Precision and Efficiency in Aerospace

One of the most significant benefits that CNC machining brings to aerospace manufacturing is its unmatched precision. Aerospace components, particularly those used in jet engines and flight control systems, demand extreme accuracy, where even a fraction of a millimeter can make the difference between a safe, functional part and a failure. CNC machines are capable of executing complex designs with exact precision, reducing the risks of defects and ensuring that every component fits perfectly.

In addition to precision, CNC machining offers remarkable efficiency. Traditional methods of aerospace manufacturing often involved multiple stages of manual intervention, each introducing potential delays or errors. With CNC machining, much of this process is automated. High-speed machining centers can rapidly produce parts with minimal human oversight, streamlining production and reducing labor costs. This improved efficiency directly contributes to reduced lead times, which is critical in meeting the fast-paced demands of aerospace production schedules.

Reducing Material Waste and Production Costs

The aerospace industry is notorious for its high production costs, and one of the key factors contributing to these costs is the waste of raw materials. Aerospace components are typically made from high-performance materials such as titanium, aluminum alloys, and specialized composites, which can be expensive. CNC machining has helped address this issue by significantly reducing material waste.

With traditional manufacturing methods, much of the material would be discarded as waste during the cutting or shaping process. However, CNC machines are programmed to minimize material waste by using highly efficient cutting paths, and advanced software can help optimize the design before production begins. This approach leads to higher material utilization, ultimately lowering production costs and making aerospace manufacturing more economically viable, especially when producing complex parts or working with high-cost materials.

Enhancing Customization and Complexity of Aerospace Parts

The ability to create custom and complex parts is another area where CNC machining is transforming aerospace manufacturing. As aircraft and spacecraft designs become increasingly sophisticated, the demand for specialized components with unique geometries, features, and materials continues to rise. CNC machines are capable of executing highly intricate designs that would be impossible to achieve using traditional manufacturing methods. This includes features such as fine grooves, contours, and even multi-axis machining for more complex shapes.

CNC machining also allows for rapid prototyping and small-batch production runs, which are common in the aerospace industry. Manufacturers can quickly produce prototypes to test the fit, form, and function of components before committing to large-scale production. This flexibility in design and production means that aerospace manufacturers can more easily adapt to changes in design specifications or requirements, ensuring that new aircraft or spacecraft models meet performance standards and regulatory requirements without long delays.

The Future of CNC Machining in Aerospace Manufacturing

As the aerospace industry continues to evolve, CNC machining is poised to play an even larger role in its future growth. Innovations such as 3D printing and hybrid manufacturing, which combine CNC machining with additive manufacturing techniques, are opening up new possibilities for creating parts with even greater complexity and efficiency. This combination of technologies is expected to reduce production times further while increasing the ability to design lightweight yet strong components, which is crucial for reducing fuel consumption in aircraft and spacecraft.

In addition, the growing focus on sustainability and environmental responsibility in the aerospace sector presents an opportunity for CNC machining to make a significant impact. With its ability to reduce material waste and improve production efficiency, CNC machining aligns well with the industry’s sustainability goals. As aerospace companies continue to prioritize environmentally friendly practices, CNC machining growth in aerospace will likely increase as manufacturers seek more sustainable, cost-effective, and innovative ways to produce high-performance components.

Conclusion

CNC machining has undoubtedly revolutionized aerospace manufacturing, offering unparalleled precision, efficiency, and cost-effectiveness. As the aerospace industry continues to push the boundaries of technology and innovation, CNC machining will remain a vital tool in producing the advanced components required for the next generation of aircraft and spacecraft. With its ability to reduce material waste, enhance customization, and support the development of more complex parts, CNC machining will continue to drive growth and transformation in aerospace manufacturing for years to come. The future of CNC machining in aerospace is bright, promising further advancements that will continue to shape the industry for the better.